What is Roll Edge Banding and How Does it Differ from Self Edge?

Traditionally self-edge has been the standard edge finish in the toilet partition industry. This has led many designers to believe self-edge is their only option when writing their specifications and they must continue in the legacy of those who have come before. However, due to modern innovation of the edge banding processes, self-edge is commonly being replaced by a modernized method called roll type banding. This new technique alleviates many of the pain points found in self-edge while raising the quality and integrity of the toilet partition system.

Self-Edge Banding – The Legacy Method

In the early days of toilet partition production, self-edge was the only method known to produce an acceptable edge match. The ability to source separate materials for every color and pattern of door was an impossible task. The logical option available was using the same material as the face of the component, leading to the term self-edge or selfsame edge.

Self-Edge Banding Can Either be Done by Machine or Hand by:

- Cutting narrow strips from the same sheet as the face sheets.

- Applying adhesive to the edge of the component.

- Securing the cut strip to the edge of the component.

- Completely covering the exposed raw edge, so as not to leave any gaps that may show as cracks in the finished component.

- Trimming the overhang off all four edges of the strip.

- Finishing the edge to remove burrs and sharp corners.

Cutting edges and faces from the same sheet of material provides the benefit of having a cohesive construction in the components of the partition system. Leading to near exact look, feel, wear, and performance no matter the environmental conditions.

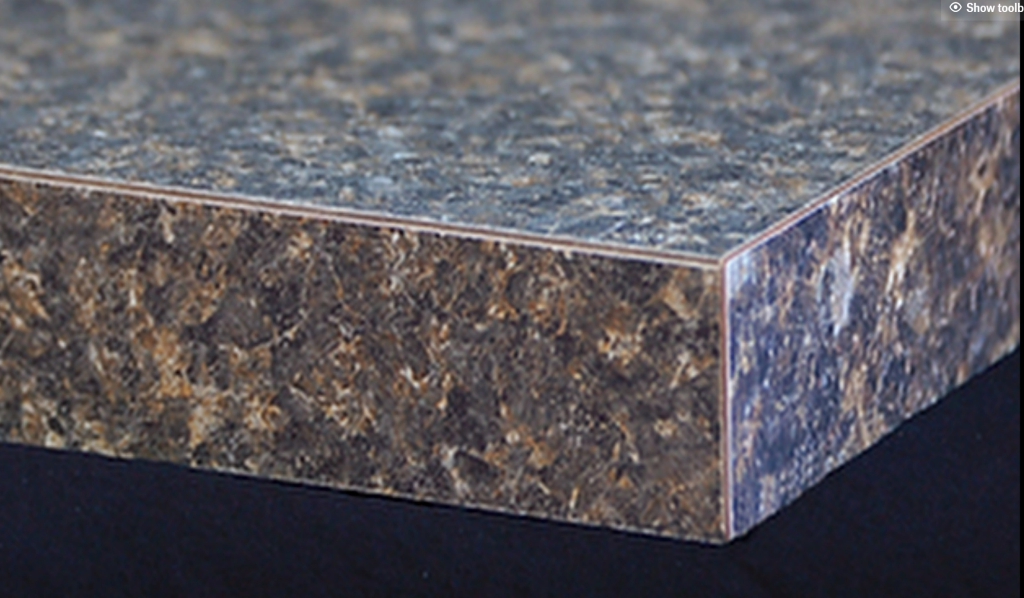

The most well-known reason not to specify self-edge is the infamous “Brown line” that is often unsightly and appears visually as a defect. The other con being the intensive labor process which contributes to a higher price point.

Roll Edge Banding – The Modern Method

In order to address the production and aesthetic limitations of self-edge banding. Manufacturers saw the modern day need to innovate. Optimized production processes led to the development of pre-made rolls of banding, which appears similar to most commercially available materials.

Roll Edge Banding is a Machine Process:

- A “pre-mill” station cuts a few thousandths of an inch, of the edge off of the component before the roll of banding is applied to provide a smooth edge for the banding to adhere too.

- The edge of the component is warmed prior to adhesive being applied.

- Adhesive is applied to the edge.

- A series of stations securely affix the banding to the component.

- The banding is trimmed, beveled, and buffed precisely to the component.

Roll edge banding often costs less and is a viable answer to the issue of the brown line. Due to it being a homogenous material, it leaves no visual lines or appearance of pick points. This makes it favorable from an aesthetic and longevity standpoint.

Although roll banding continues to improve in the varieties of colors, patterns, finishes, and textures available, it is not readily available in every color or pattern. If your design requires an exact edge match to the face of the component, self-edge is widely available as a legacy method. However, if cost is a factor and the close visual match is acceptable then consider specifying roll edge banding for your project. Roll edge banding is the modern method that provides an answer for the modern partition system design.