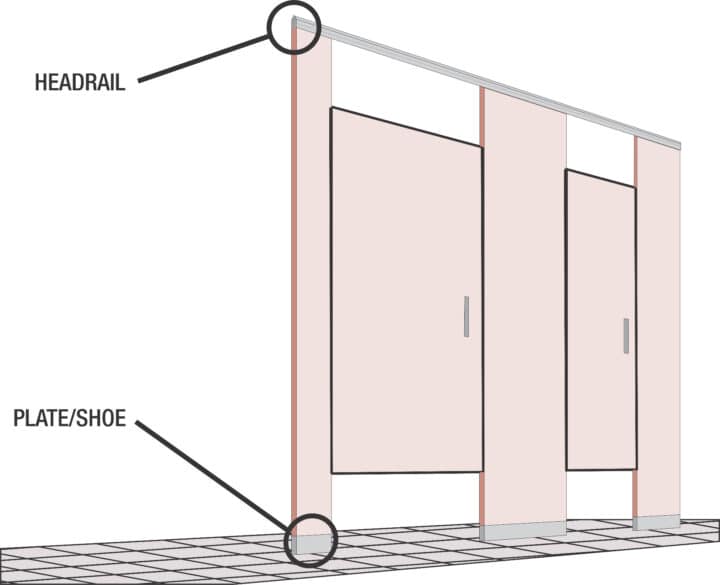

Headrail Braced Partitions

Design with Headrail BracedWhen your commercial restroom design calls for durability, cost-effectiveness, and adaptability, headrail braced partitions provide the support and flexibility you need.

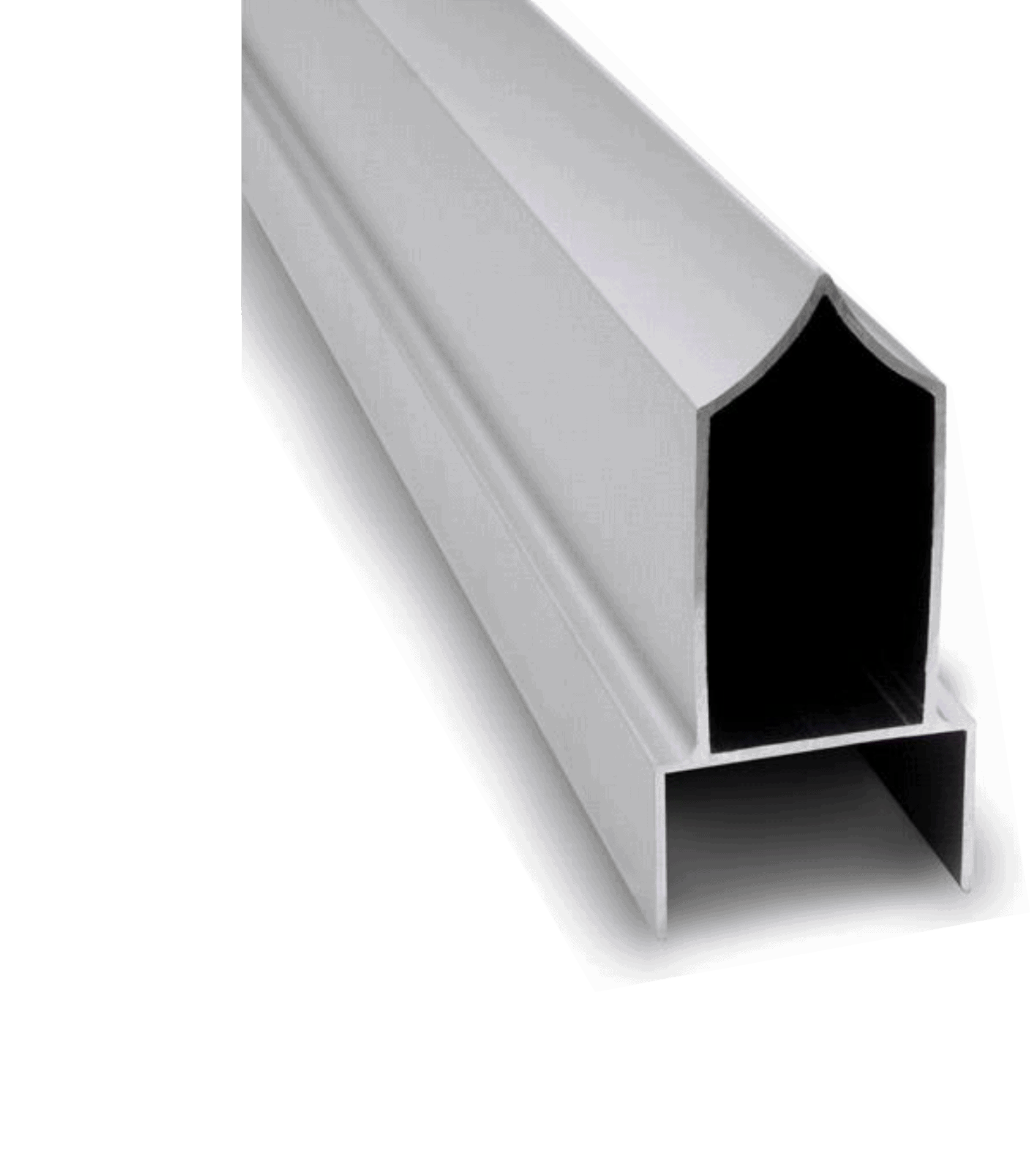

Headrail

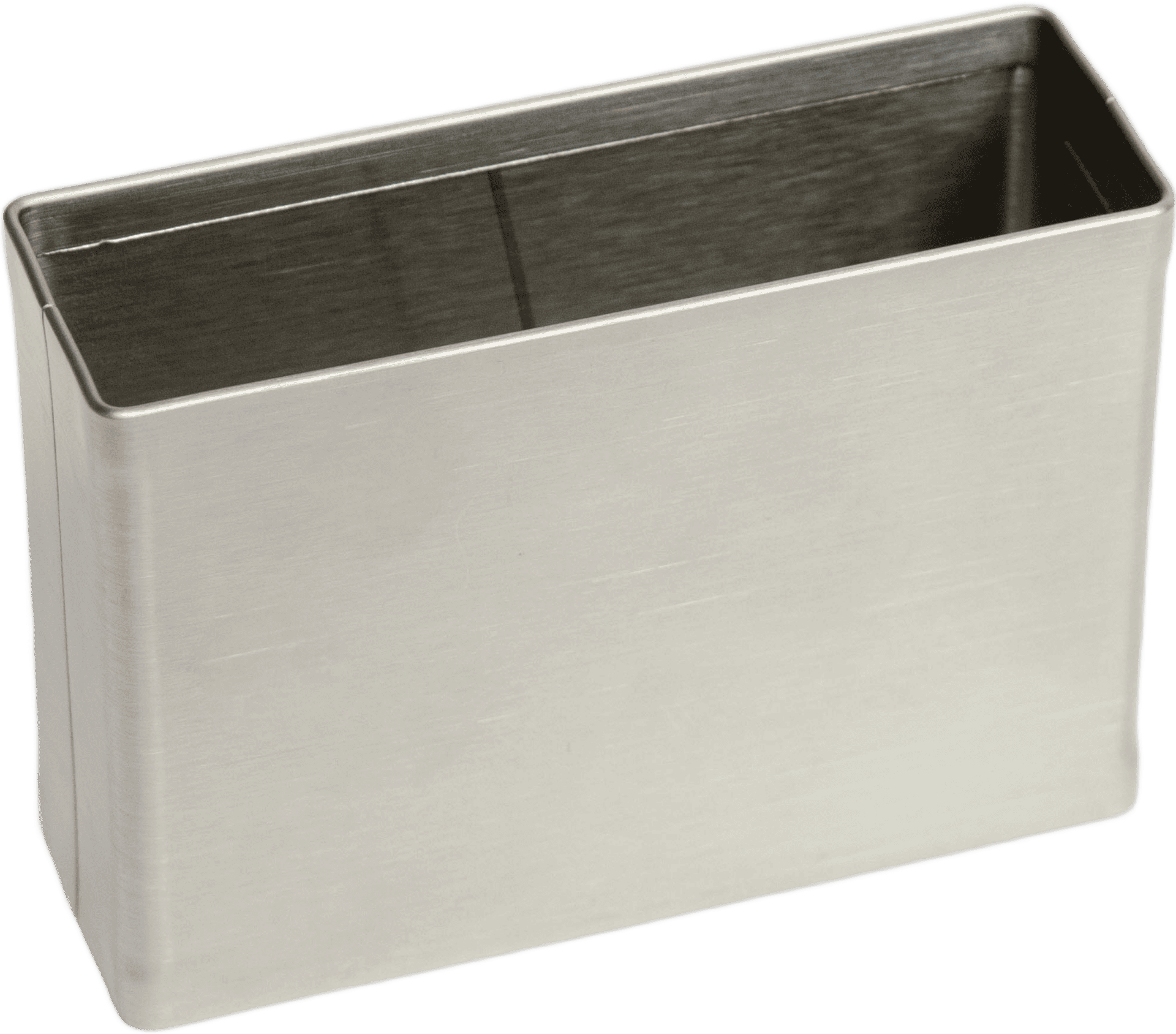

Shoe & Plate

What is Headrail Braced?

Headrail braced is a mounting method using a ridged overhead rail securely fastened to adjacent walls and the top of each pilaster. Typically, the headrail is made of extruded aluminum and includes an anti-grip feature. Headrail may be made to match the finish of the partitions. Floor connections are typically accomplished with floor-plates which are concealed by a shoe. Other floor connection options are available to suit specific aesthetics.

Headrail

Stabilizes pilasters to walls

Shoe & Plate

Mounts pilasters securely to floor or ceiling.

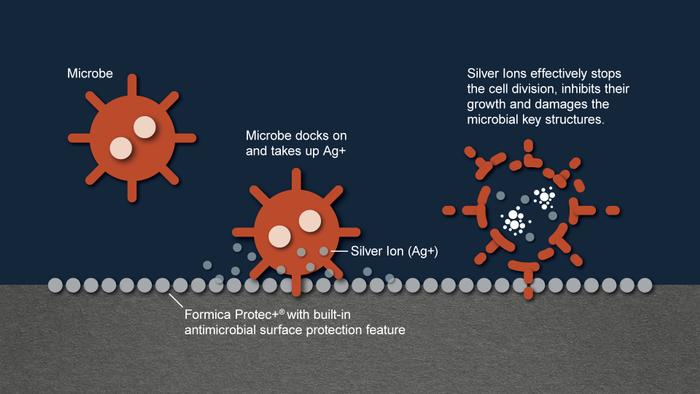

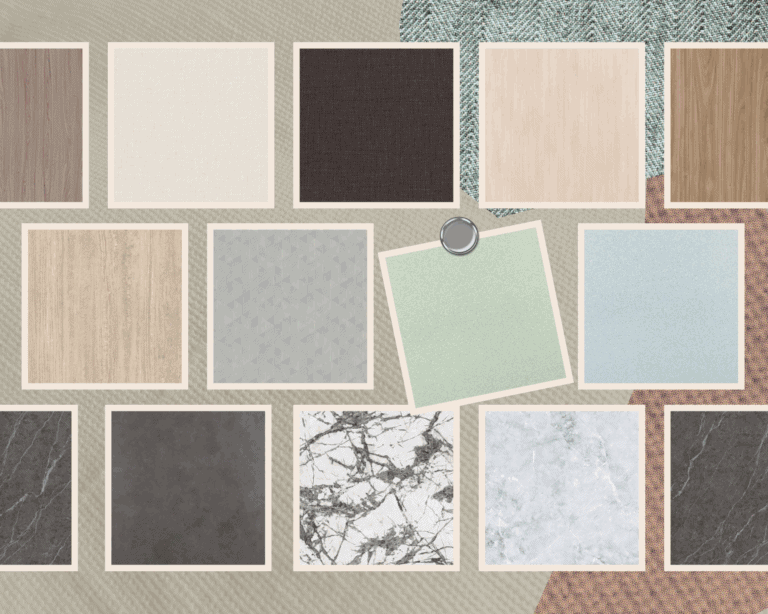

Compatible Materials

Materials

Explore our collection of material options for headrail braced partitions. Each choice provides unique benefits to enhance your restroom design.

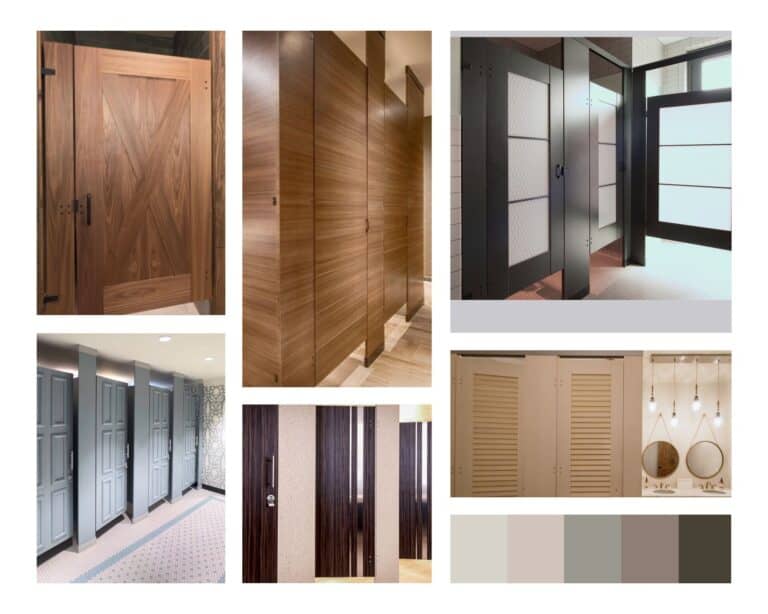

Door Styles

Compatible Door Styles

Discover the range of door styles available for headrail braced partitions. Each option offers a distinct aesthetic, allowing you to transform the look of your space with your selection.

Louver

Plantation-style doors with angled slats for aesthetic appeal and airflow in restroom partitions

Molding

Decorative molding trim applied to commercial restroom partition components.

Captured Panel

Stile and rail construction with captured panel inserts and optional midrails.

Door Lite

Stile and rail construction with acrylic or glass translucent inserts.

Engraving

Featuring standard or project-specific patterns cut directly into restroom partition material.

Flat Panel

Flat panel doors in a variety of materials, patterns, and finishes for commercial restroom partitions

Inlay

Doors featuring designs consisting of precisely fitted materials.

Considerations When Using Headrail Braced

Headrail Braced offers numerous advantages, but certain features should be evaluated to ensure it meets your project’s requirements.

FeaturesBudget-Friendly

Headrail braced is generally the most economical option among partition mounting styles. It reduces material costs associated with tall pilasters and minimizes shipping expenses for tall components, making it a budget-friendly choice for many projects.

Stability and Support

Headrail braced mounting provides excellent stability without requiring ceiling attachment. This mounting style is ideal for areas with high or irregular suspended ceilings. The system offers additional support for partition components, enhancing overall structural integrity.

Adaptable

The headrail braced system accommodates various restroom layouts and obstructions, allowing for flexible design solutions. It allows for easy integration of overhead door closers and adapts well to different pilaster heights and configurations, providing versatility in application.

Easy Upkeep

This mounting style requires minimal post-installation maintenance, simplifying long-term upkeep. The system also simplifies future repairs or adjustments, reducing maintenance costs over time.

Aesthetics

Headrails are available in a variety of powder-coated colors. Alternatively, headrail may be made from the same material and finish as the partition components, though this choice will impact both cost and installation time.

How to Specify Ironwood

Follow our easy three-step process to start using Headrail Braced in your design:

The Process- 1

Go to the Configurator

Our configurator will help guide your choices of material, mounting style, door option, hardware, etc. to specify your toilet partitions.

- 2

Generate Your Specification

Once you have made your selections, the configurator will generate a spec and other helpful resources for you.

- 3

Contact Us With Any Questions

Call us at 360-965-6590 or email us at [email protected].

Deeper Dive & Resources

Gain a deeper understanding of Headrail Braced by exploring resources and expert insights.

Headrail-braced partitions offer flexibility in mounting configurations. While the standard implementation uses floor plates and shoes, alternative options include L-brackets and pedestals.

Ironwood Manufacturing offers custom headrail options for designers seeking unique aesthetic solutions or specific material requirements:

Material

Custom headrail is available in plastic laminate, wood veneer, or compact laminate, providing an alternative to standard extruded aluminum headrail.

Dimensions

- Height: Custom headrail is precisely 3″ tall, balancing strength and adaptability

- Thickness: Matches the pilaster thickness for a cohesive look

- Length: Maximum single-piece length is 105″. Longer runs require splicing

Connections

- Splicing: In-line connections use two 1/4″ x 1″ dowel pins per splice.

- Tee and Wall Connections: Utilize L-brackets for secure attachment.

Installation Considerations

- A minimum 12″ gap is required between the top of the custom headrail and the ceiling for proper installation

- Installers must cut and seal custom headrail in the field. Sealing cut ends is crucial for maintaining warranty coverage

Custom headrail offers an opportunity to create a cohesive design aesthetic while maintaining the structural benefits of headrail braced partitions. Designers should consider material compatibility, installation requirements, and overall visual impact when specifying custom headrail options.

Headrail can be powder coated in a range of colors based on a specific color chart. While exact matching to partition colors is not possible, this option allows for selecting complementary accent colors. Powder coating enhances durability and offers superior resistance to chipping, scratching, and fading compared to traditional paint finishes.

Our preferred powder coat vendor is Cardinal. Colors from other vendors are available but costs and lead times will be negatively impacted. In addition, touch up paint may not be available for other vendors.

Headrail

The standard headrail is constructed from clear anodized aluminum, and designed with an anti-grip profile to deter its use as a pull-up bar. Other available finishes include powder coating and custom headrails made from materials that match the partition components.

Floor Connections

Standard floor plates (with covering shoes) provide secure anchoring for the system. Anchoring these plates requires a 2″ floor penetration. Leveling bolts ensure proper alignment and stability, facilitating accurate installation.

Alternative floor anchor options include pedestals and L-brackets for varied installation requirements. Pedestals and L-brackets require a 2″ floor penetration for anchoring.

Pilasters

Standard height pilasters accommodate most commercial applications. Standard pilaster heights for headrail braced include:

- 82″ pilasters for 58″ and 72″ tall doors.

- 94.5″ pilasters for 84″ tall doors.

Custom heights are available for specific design requirements allowing for consistency with overall design schemes.

Headrail Braced partitions attach pilasters to the floor with minimal floor reinforcement required. Extruded aluminum headrail is attached to the top of the pilasters, providing excellent structural stability. Limited structural requirements, low cost and good stability combine to make this our most popular style.

The clear anodized aluminum headrail is shaped to deter gripping, pull-ups or other types of activities. Headrail is also available in powder coat finishes.

Because of its strength, this style is recommended for areas that expect heavy traffic or the likelihood of rough use. This style is also recommended for restrooms with high ceilings where other other mounting style partitions are not feasible.

This style requires the least amount of post-installation adjustments.

Frequently Asked Questions

Can headrail braced be used with any partition material?

Headrail braced is compatible with a wide range of partition materials, including compact laminate, high-pressure laminate, wood veneer, stone, and solid surface materials. The choice of material does not generally affect the mounting style’s functionality, allowing for design flexibility to meet aesthetic and performance requirements.

How does headrail braced perform in high-humidity environments?

Headrail braced performs well in high-humidity environments. The elevated position of the headrail helps protect it from direct water exposure. When specified with moisture-resistant partition materials and appropriate hardware finishes, this mounting style can provide durable and long-lasting installations in humid conditions.

Can existing partitions be retroffited to headrail braced?

Yes, existing partitions can be retrofitted to headrail braced, but consulting with an Ironwood specialist is recommended to determine feasibility and any necessary modifications. Some components and hardware may need to be replaced or upgraded.

How does headrail braced impact the overall privacy of the stalls?

Headrail braced does not inherently affect stall privacy. The level of privacy is primarily determined by the height of the partitions, door designs, and any additional privacy features incorporated into the system. Headrail braced partitions can be designed with extended height components, no-sightline systems, and other privacy enhancements to meet specific requirements.

Is headrail braced ADA compliant?

Headrail braced mounting style can be configured to be fully compatible with federal ADA guidelines. When installed correctly, standard-supplied hardware options are fully ADA compliant. The layouts and mounting style ensure compliant grab bar and door operations are not hindered.

How does headrail braced compare to other mounting styles in terms of installation time?

Headrail braced typically requires less installation time compared to other mounting styles. The absence of ceiling attachments simplifies the process, and the headrail provides additional support during installation. Exact installation times can vary based on specific project conditions and installer experience.

Can headrail braced accommodate oversized doors or panels?

Yes, headrail braced can accommodate oversized doors or panels. The additional support provided by the headrail allows for greater flexibility in component sizes. However, it is important to consult with an Ironwood design professional for specific size limitations and any necessary modifications to ensure proper functionality and stability.

Is it possible to customize the appearance of the headrail?

Headrail customization options are available to align with specific design requirements. While the standard headrail is typically clear anodized aluminum, it can be finished in various colors to complement the partition materials. For unique design, custom headrail options may be explored in consultation with Ironwood.

What type of maintenance is required for headrail braced?

Headrail braced partitions require minimal maintenance. Regular cleaning with mild soap and water is typically sufficient for both the partitions and the headrail. Periodic checks of hardware tightness and door alignment may be necessary, particularly in high-traffic areas. The open floor design facilitates easy cleaning underneath the partitions.

If you can’t find the answer you’re looking for, feel free to reach out to us directly and we’ll be happy to assist you!

Featured Headrail Braced Bathroom Stalls

GalleryBrowse through examples of headrail braced bathroom stalls, highlighting their aesthetic appeal and practical benefits.

Explore Portfolio