Compact Laminate

Design With Compact LaminateWhen your commercial bathroom design requires moisture resistance, durability, privacy, and beauty, compact laminate is the right partition material for the job.

Lead Time: 12 Weeks

Budget: $$$

Compact Laminate Vendors

Is your pattern available in Compact Laminate?

We provide materials from many manufacturers and have an extensive selection of patterns and colors to select from. You may verify the availability of your color and pattern using the links provided. For additional options, contact us, we are happy to assist.

What is Compact Laminate?

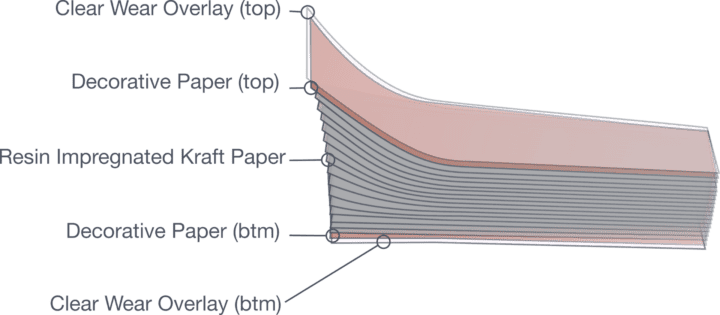

Compact Laminate is a durable material composed of layers of kraft paper treated with resin and fused together under high heat and pressure. The result is a solid panel offering exceptional resistance to moisture, impact, and wear, ensuring longevity and reliability in commercial restroom partitions.

Compact Laminate Use Cases

Application

Compact Laminate is an ideal choice for high-traffic environments where durability, moisture resistance, and long-lasting performance are essential. Its versatility makes it perfect for a wide range of commercial restroom applications.

Schools & Universities

Correctional Facilities

Military Facilities

Fitness Centers

Cultural Centers

Aquatic Centers

Government Buildings

Stadiums & Arenas

AND MORE

Considerations When Using Compact Laminate

Compact Laminate offers numerous advantages, but certain features should be evaluated to ensure it meets your project’s requirements.

FeaturesWet Environment

Compact Laminate bathroom partitions are resistant to water, and therefore a great choice for humid and wet areas. Some brands are suitable for very wet areas such as showers.

Heavy use

Compact Laminate is very durable, withstanding impacts and gouging. It is also easy to clean, even when marked by pens, pencils, or markers.

High Privacy Design

Compact Laminate components can be set within 1/2” of the floor and ceiling. Door and pilaster edges can be machined and interlapped, completely removing sightline gaps from the door without the use of astragals.

Color Coordinated Banding

Ironwood’s unique HeH edge banding coordinates with the compact laminate color or pattern you select, eliminating the black core edges common in commercial restrooms.

15 Year Warranty

Ironwood compact laminate restroom partitions have a 15-year warranty. This long warranty is an attractive option for those looking for a long-term bathroom stall value.

Height Restrictions

Maximum door height of 84” and maximum pilaster height of 120”. Doors or pilasters taller than this are at risk to bend or cup.

Stall Depth

Compact Laminate material cannot be spliced and is not available in sheets wider than 60”. An additional pilaster must be added, along with additional hardware when required.

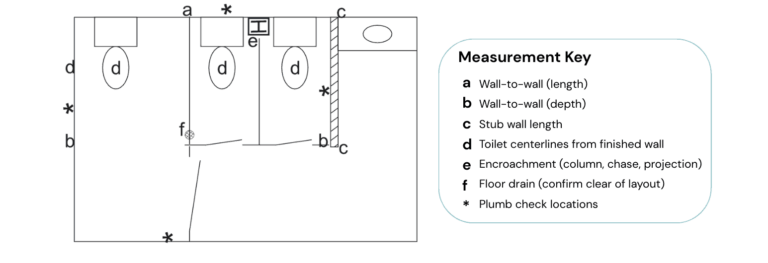

How to Specify Ironwood

Follow our easy three-step process to start using Compact Laminate in your design:

The Process- 1

Go to the Configurator

The Ironwwood Configurator will help guide your choices of material, mounting style, door option, hardware, etc. to specify your toilet partitions.

- 2

Generate Your Specification

Once you have made your selections, the configurator will generate a spec and other helpful resources for you.

- 3

Contact Us With Any Questions

Call us at 360-965-6590 or email us at specs@ironwood-mfg.com.

Deeper Dive & Resources

Gain a deeper understanding of Compact Laminate by exploring resources and expert insights.

Ironwood compact laminate partitions are manufactured with the following thicknesses:

- ¾” (slab doors and pilasters)

- 1” (stile and rail doors and pilasters)

- ½” (panels and urinal screens)

- ¼” (louver slats)

Standard compact laminate is Class B fire rated. Class A fire rating is an additive option. Note that Class A is considerably more expensive.

Compact Laminate partitions are often a good choice when surfaces must be free of germs. Some, but not all, compact laminate products can be manufactured with an antimicrobial coating. We recommend cleaning be done simply with soap and water, but most commercial cleaning products do not diminish material performance.

Compact Laminate components can be manufactured with full custom and semi-custom patterns and colors, including images. Contact us if you are interested in exploring full prints.

Here is more information about compact laminate toilet partitions, for those wanting to go a little deeper.

AKA (Also Known As)

Compact Laminate is also known as Phenolic. Some companies have been marketing phenolic with this name for the last few years. Other names for compact laminate include compact grade laminate, solid phenolic core, and more.

Edge Holding Limitations

Compact Laminate sheets are most commonly manufactured by applying high temperatures and pressure to layers of kraft paper impregnated with phenolic resins. This core is covered with a decorative surface paper sheet and a transparent, water-resistant overlay to give the desired color and pattern. This process results in a durable material with a matte finish.

One consequence of this layered manufacturing process is poor edge-holding capability. This means that fasteners should not be screwed or otherwise mounted into the edge of a compact laminate component.

The faces of compact laminate products have very strong fastening characteristics, due to the same layered construction.

Inexpensive Compared to Other Durable Materials

Compact Laminate toilet partitions offer a stylish and cost-effective alternative to more expensive options for public restrooms, such as solid surfaces and quartz. Compact Laminate is an excellent material choice for reducing costs without sacrificing quality, aesthetics, or performance.

Unheated or unconditioned environments

Compact Laminate is also used for exterior cladding and performs well across a wide temperature range. Care must take to consider specifying UV-resistant compact laminate in external applications. Uniform temperature and airflow are also required to avoid warping. This means the front and back faces should not be subject to widely differing temperatures.

Frequently Asked Questions

Can you have a floor gap of 1″ or less in bathroom stalls?

Phenolic material supports floor gaps as small as 1/2″. Gaps smaller than 1/2″ may be possible but will require additional engineering and special care. Please contact us if you need a gap smaller than 1/2″ for your project.

What are your standard component heights?

Our phenolic doors and panels come in 58″, 71.5″, and 84″. We offer custom heights as well.

What mounting styles are available in compact laminate?

Phenolic restroom stalls are available in the following mounting styles:

- Headrail Braced

- Floor to Ceiling

- Floor Mount (additional costs and considerations)

- Ceiling Hung (additional costs and considerations)

- Wall Mount (additional costs and considerations)

What is the lead time for compact laminate material?

Phenolic’s lead time is typically 8 weeks but can take up to 20 weeks with some suppliers.

What is the difference between phenolic and compact laminate?

They are the same material. Several suppliers have been marketing phenolic as compact laminate for the last few years.

How are compact laminate louvered doors manufactured?

Louvered doors are manufactured using stile and rail construction with the louver slats mortised into the stile. The slats are made of 0.25″ thick phenolic with black edges. The stiles and rails have an edge band coordinated with the selected pattern.

Do the edges of compact laminate components have to be black?

They do not! Solid phenolic cores have a small selection of color-thru phenolic options rather than black core phenolic which you can choose from. Ironwood also offers color-coordinated edge banding.

Can stile and rail doors be built from phenolic?

Yes. Phenolic components can be built in a stile and rail configuration. Some of our popular stile and rail configurations include louvers, captured panels, and door lites.

If you can’t find the answer you’re looking for, feel free to reach out to us directly and we’ll be happy to assist you!

Featured Compact Laminate Bathroom Stalls

GalleryBrowse through examples of compact laminate bathroom stalls, highlighting their aesthetic appeal and practical benefits.

Explore Portfolio