Molding Partitions

Design with Applied Molding DoorsDesign with applied molding doors to add sophistication and visual interest to your commercial restroom partitions. Molding doors are a cost-effective way to significantly upgrade your space.

What are Molding Doors?

Molding doors are partition components enhanced with decorative trim applied to create geometric patterns (typically rectangular). This versatile door style adds depth and elegance to commercial restrooms and can be updated to complement various designs.

Compatible Materials

Materials

Molding doors are available in various high-quality materials, each offering unique benefits for different commercial restroom environments.

Compatible Mounting Styles

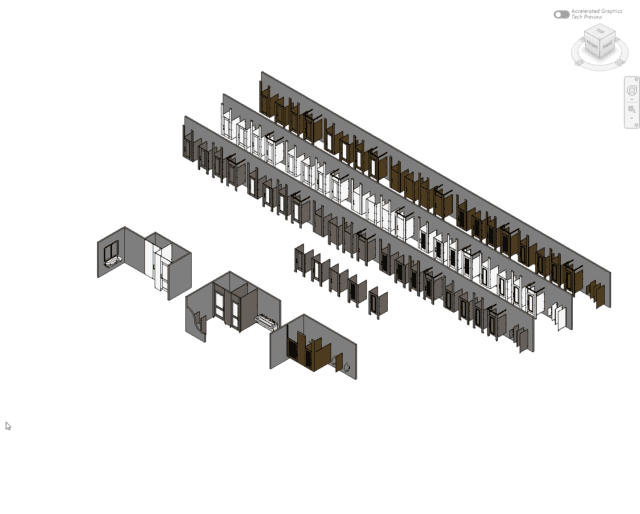

Mounting StylesMolding doors can be integrated with multiple mounting styles, providing flexibility in design and installation for diverse commercial restroom layouts.

Headrail Braced

Floor mounted pilasters with overhead aluminum bracing for stability.

Floor to Ceiling

Pilasters secured at the floor and ceiling with minimal visible hardware.

European

Pilasters with overhead headrail and floor pedestals blend style and strength.

Ceiling Hung

Pilasters attached solely to the ceiling offer open floor space and a clean look.

Floor Mount

Partition pilasters are anchored to the floor only, resulting in low-profile elegance.

Considerations When Using Molding Doors

Explore the key features and considerations of molding doors to determine their suitability for your commercial restroom project.

FeaturesAesthetics

Choose from various molding profiles, materials, and finishes to create a unique look that complements your overall design vision.

Component Flexibility

Molding can be applied to the front or back of any partition component, allowing for creative design solutions in various restroom layouts.

Visual Upgrade

Molding doors provide a significant visual enhancement compared to standard slab doors, elevating the restroom’s appearance.

Cleaning Requirements

Moldings may require special care to avoid damage from cleaning solutions, especially for wood options.

Accessory Interference

Attention must be paid to stall dimensions when adding moldings, as they may interfere with toilet accessory placements.

Wet Area Suitability

Wood moldings are not recommended for wet areas due to potential damage.

How to Specify Ironwood

Follow our easy three-step process to start using Molding in your design:

The Process- 1

Go to the Configurator

The Ironwwood Configurator will help guide your choices of material, mounting style, door option, hardware, etc. to specify your toilet partitions.

- 2

Generate Your Specification

Once you have made your selections, the configurator will generate a spec and other helpful resources for you.

- 3

Contact Us With Any Questions

Call us at 360-965-6590 or email us at specs@ironwood-mfg.com.

Deeper Dive & Resources

Discover detailed information about molding doors to make informed decisions for your commercial restroom design.

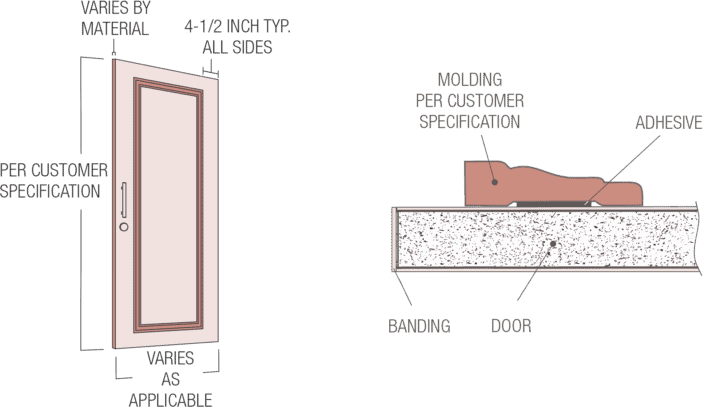

Ironwood offers a range of standard molding profiles to suit various design preferences:

- Shaped profiles (see our standard molding profiles sheet)

- Rectangular

- Custom profiles are available upon request

Note that moldings made of compact laminate are available, but only in a rectangular profile.

Molding is securely attached to partition components using adhesive fastening methods, ensuring durability and longevity.

Molding can be added to various partition components, including:

- Doors

- Panels

- Pilasters

- Transoms

This versatility allows for a cohesive design throughout the restroom.

Note the following limitations:

- Components with moldings must be at least 23″ wide and at least 23″ tall in order to accommodate the minimum molding frame sizes

- Moldings should not be applied to urinal screen faces facing a urinal, or panels next to a urinal

Molding doors can be further customized by combining them with:

- Captured panels

- Door lites

In these combinations, molding can either frame the insert or overlay it, providing additional design possibilities.

While molding doors offer exceptional aesthetics, it’s important to consider the following maintenance aspects:

- Some cleaning solutions may not be suitable for real wood or painted molding

- On-site repairs to molding can be challenging

- Wood molding is not recommended for use in wet areas

- Moldings should not be applied to urinal screen faces facing a urinal, or panels next to a urinal

- Interior panel molding may interfere with toilet accessory mountings, requiring careful planning during design

Moldings can be applied to both the front and back of components.

Multiple molding shapes, such as rectangles or diamonds, can be used to create custom designs.

Frequently Asked Questions

What is the cost difference between molding doors and standard slab doors?

Molding doors are an inexpensive upgrade from slab doors, offering a significant visual enhancement at a modest price increase. The exact cost difference depends on the chosen materials and complexity of the design.

How durable are molding doors in high-traffic commercial restrooms?

Molding doors are designed for commercial use, but they may require additional care in high-traffic areas. It’s important to consider the environment and expected usage when selecting molding doors for your project.

Can molding be applied to both sides of a component?

Yes, molding can be applied to both the front and back of a component. Our standard is to apply molding only to the front unless otherwise specified.

Can I use custom molding profiles for my project?

Yes, Ironwood offers custom molding profile options in addition to our standard selections. Our team can work with you to create a unique molding design that meets your specific aesthetic requirements.

What are the cleaning recommendations for molded doors?

For wood moldings, avoid harsh chemicals. For other materials like laminate, standard cleaning methods should suffice.

If you can’t find the answer you’re looking for, feel free to reach out to us directly and we’ll be happy to assist you!

Featured Molding Bathroom Stalls

GalleryBrowse through examples of molding toilet partitions, highlighting their aesthetic appeal and practical benefits.

Explore Portfolio