The toilet partition design process goes through many steps before it reaches the procurement phase. This article addresses the next steps after Ironwood receives a signed quote to bring the project from submittal to release.

Ironwoods Project Management Process

Because of the wide selection of features available, Ironwood does not have off-the-shelf premade components. Every job is made to order as each project is different and requires the same level of care and quality control as the next. Due to this variety, Ironwood has different project management processes than other toilet partition manufacturers.

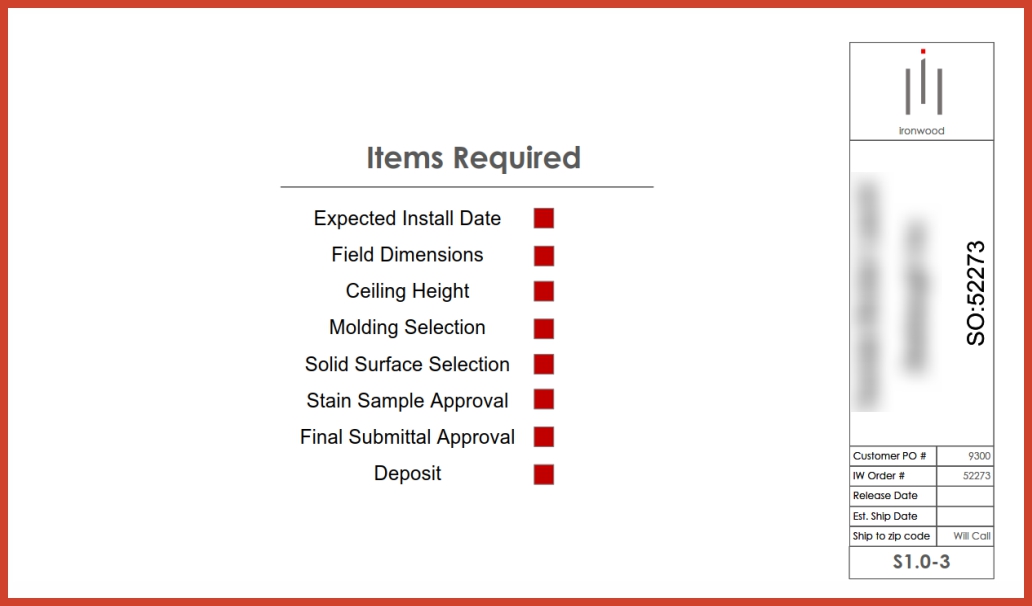

Submittals and Deposits

When Ironwood receives a signed quote, the submittal process begins. During this stage, a dedicated project manager is assigned. The project manager will be a guide and point of contact for any stakeholder throughout the process. The start of this phase begins via an email containing the first round of submittal drawings, marking the beginning of the revision and approval process.

Expected Installation Date

An anticipated installation date helps the project manager plan and schedule future steps in the process. By forecasting the schedule, the project manager can gather time sensitive information and clarify as necessary to maintain the project timeline.

Field Measurements

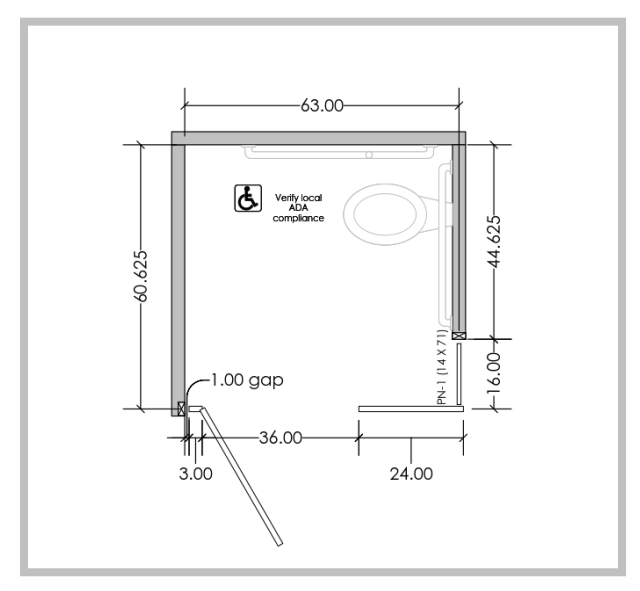

Accurate field measurements help ensure a better fit of the partition components and help avoid the need for field adjustments. When partitions feature zero-sightline privacy, installation tolerances are tighter than traditional flat edge doors and pilasters.

Sample Approvals

Partitions can be ordered with a wide range of options.

Multiple configurations and features are available to suit every project. When a project has a wood veneer, acrylic insert, or powder coated hardware, Ironwood sends sample material for approval. These approvals are critical to ensuring the end user gets exactly what was envisioned and reduces rejection of product due to color mismatch.

Final Submittal

Ironwood has a measure twice, cut once mindset. Changing the doors from 72 to 84 inches after they have been made is impossible without re-ordering new material and lengthening the project timeline.

To avoid this, Ironwood requires final submittal approvals prior to ordering materials and starting the production process.

Deposit

Another requirement prior to material purchase and production is the deposit. Ironwood’s standard terms are 70% deposit prior to release, and balance due net 30 after shipping. After a successful track record is established, more favorable terms may be available.

Once these items are received and the project is released, lead times start at 6 weeks plus shipping for standard high pressure laminate partitions and can increase depending on material and vendor lead times. Anticipated lead times can be found on individual Ironwood quotes.