Restroom projects often involve multiple priorities, including design, durability, budget, and hygiene. Material selection plays a key role, particularly when antimicrobial properties are a consideration.

HPL vs. Compact Laminate: Understanding the Difference

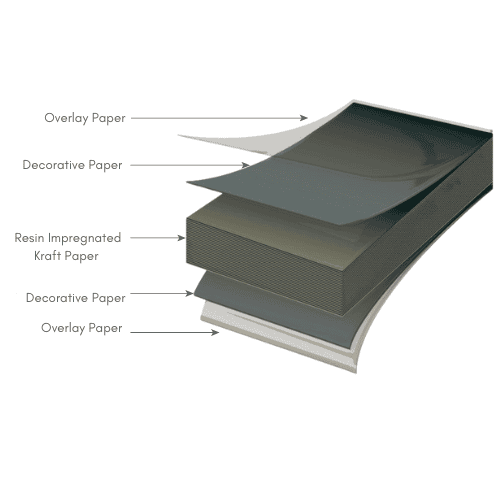

Ironwood manufactures partitions using both High Pressure Laminate (HPL) and Compact Laminate (Phenolic). These materials often use the same surface patterns, so their appearance is nearly identical. The difference lies in the core construction.

- High-Pressure Laminate (HPL):

It is a good choice when budgets are tight and conditions are not excessively wet. HPL is moisture-resistant, not waterproof. - Compact Laminate (Phenolic):

Made by compressing layers of resin impregnated kraft paper, this material is dense, impact resistant, and highly water resistant. It is a reliable choice for environments with heavy use or frequent moisture.

The Antimicrobial Landscape: Prevention vs. Elimination

Not all antimicrobial technologies work the same way, and understanding these differences is critical when selecting materials for restroom partitions where hygiene is paramount.

Bacteriostatic vs. Bactericidal: The Fundamental Divide

- Bacteriostatic antimicrobials prevent bacterial growth and reproduction without necessarily killing existing bacteria. These technologies create an environment where microbes cannot multiply, effectively stopping colonies from establishing themselves on the surface.

- Bactericidal antimicrobials actively kill bacteria and other microorganisms on contact. These are the aggressive fighters in the antimicrobial world, designed to eliminate pathogens rather than simply contain them.

Both types of antimicrobial protection can be effective in toilet partition applications. The best option depends on the facility’s requirements, usage patterns, and cleaning procedures.

Silver-Based Antimicrobial Technology: The Gold Standard

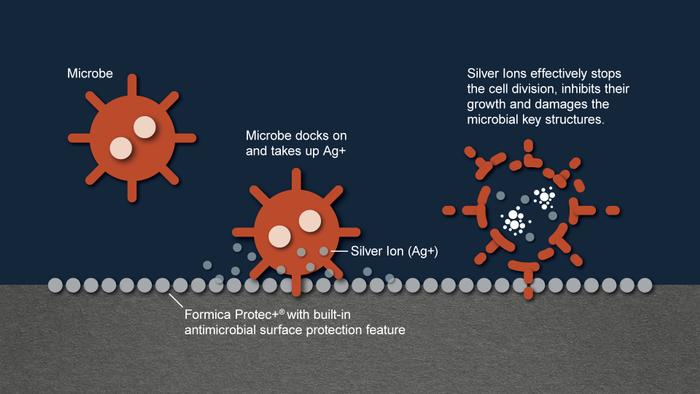

Silver-based antimicrobial additives represent one of the most effective approaches for laminate surfaces. These systems work through multiple mechanisms:

- Ionic Release: Silver ions are gradually released from the surface, disrupting bacterial cell walls and interfering with cellular processes.

- Contact Killing: When bacteria come into direct contact with silver-embedded surfaces, the metal ions penetrate cell membranes, causing cellular damage and death.

- Sustained Protection: Unlike surface-applied antimicrobial coatings that can wear away, silver additives integrated during the manufacturing process provide lasting protection throughout the material’s lifespan.

Silver-based systems maintain effectiveness even when surfaces become wet, a critical advantage in restroom environments.

Options:

- Formica – BioCote® Antimicrobial Additive

- Wilsonart HD – Wilsonart® HD® designs come standard with Antimicrobial Protection. No upcharge or special order required with HD® designs. Antimicrobial is available on all Wilsonart options, it may incur an additional cost.

- Abet Laminati – Lamishield

Organic Antimicrobials: Engineered Molecules

Synthetic organic antimicrobials, such as quaternary ammonium compounds and triclosan derivatives, offer targeted antimicrobial action:

- Membrane Disruption: Causes leakage and death of bacterial cells.

- Enzyme Inhibition: Prevents essential bacterial processes.

- Selective Toxicity: Safe for humans but lethal for microbes.

Options:

Integration Methods: Getting Antimicrobials into Laminates

The performance of antimicrobial systems depends on how they are integrated into the material.

- Resin Bath Integration: For HPL, additives are introduced during the final resin bath.

- Core Integration: In compact laminates, antimicrobials can be embedded throughout the core.

- Surface Application: Applied as topcoats; less durable for high-wear areas.

Performance Considerations for Restroom Applications

Key factors when selecting antimicrobial laminates for partitions:

- Moisture Resistance: Silver Ion systems perform well when wet.

- Chemical Compatibility: Must withstand disinfectants and cleaning agents.

- Durability: Must remain effective despite surface wear.

Making the Right Choice

Your selection between bacteriostatic and bactericidal often depends on cleaning protocols and risk tolerance:

- High-Traffic Public Restrooms: Choose bactericidal systems like silver.

- Controlled Access Facilities: Bacteriostatic systems may suffice.

- Healthcare Environments: Opt for a combination approach.

As we continue navigating a health-conscious world, antimicrobial laminates offer more than cleanable surfaces—they offer confidence and protection. Ironwood works to align material choices with each project’s performance needs, budget, and hygiene goals. We are here to support your team.

Note: Solid Surface material such as Corian is seamless and nonporous, making it impervious to water, moisture, and heat. It has natural anti-microbial and infection-controlling surface qualities that naturally inhibit the growth of mold, mildew, and dangerous bacteria.