High Pressure Laminate Partitions

Design with High Pressure LaminateHigh Pressure Laminate (HPL) offers a wide variety of finishes and patterns. With the shortest lead time and budget-friendly pricing, HPL is an excellent choice.

Lead Time: 6 Weeks

Budget: $$

High Pressure Laminate Vendors

Is Your Pattern Available In High Pressure Laminate?

We provide materials from many manufacturers and have an extensive selection of patterns and colors to select from. You may verify the availability of your color and pattern using the links provided. For additional options, contact us, we are happy to assist.

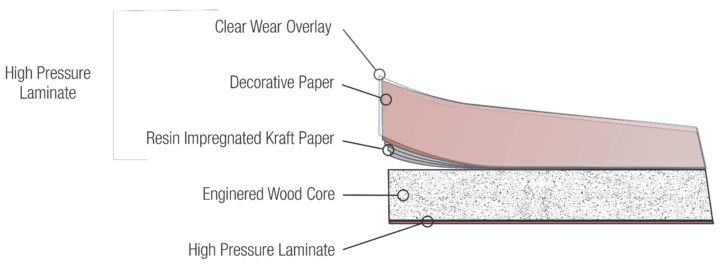

What is High Pressure Laminate?

High Pressure Laminate (HPL) is a durable and versatile material composed of multiple layers: The wear layer is a protective overlay that shields the decorative layer—the visible design of the laminate, whether woodgrain, patterned, or solid color. Behind these two front layers is 6 to 8 sheets of resin. Two of these sheets are adhered to an engineered core and then heat and pressure is applied to create a single component to be used in toilet partitions.

High Pressure Laminate Use Cases

Application

High Pressure Laminate is an ideal choice for commercial restroom environments that require a balance of aesthetics and functionality. Its durability, moisture resistance, and wide range of design options make it suitable for various applications.

Restaurants

Retail Environments

Office Buildings

Fitness Centers

Country Clubs

Hotels

Cultural Centers

AND MORE

Considerations When Using High Pressure Laminate

High Pressure Laminate offers numerous advantages, but certain features should be evaluated to ensure it meets your project’s requirements.

FeaturesVersatile

HPL toilet partitions offer a wide range of colors, patterns, and finishes, allowing for versatile design options that can complement or enhance any commercial restroom.

Durability

HPL partitions are known for their durability and resistance to wear, making them suitable for high-traffic environments. They resist shallow scratches and stand up to general wear and tear.

Moisture Resistance

While not completely waterproof, HPL partitions offer good resistance to the standard moisture and humidity of restroom environments. However, they are not suitable for proximity to shower stalls or high humidity areas.

Maintenance

HPL partitions are easy to clean and maintain, requiring only regular wiping with standard cleaning products. Their non-porous surface resists stains and bacteria growth.

Budget Friendly

HPL partitions offer a good balance of quality and affordability. They provide excellent value considering their durability and low maintenance requirements.

Customization

HPL allows for various customization options, including digital printing for unique patterns or graphics like logos, and landscapes.

Sustainability

Many HPL products are available with low-VOC emissions and can contribute to LEED credits. Some components may be recyclable at the end of their lifecycle.

How to Specify Ironwood

Follow our easy three-step process to start using High Pressure Laminate in your design:

The Process- 1

Go to the Configurator

The Ironwwood Configurator will help guide your choices of material, mounting style, door option, hardware, etc. to specify your toilet partitions.

- 2

Generate Your Specification

Once you have made your selections, the configurator will generate a spec and other helpful resources for you.

- 3

Contact Us With Any Questions

Call us at 360-965-6590 or email us at specs@ironwood-mfg.com.

Deeper Dive & Resources

Gain a deeper understanding of High Pressure Laminate by exploring resources and expert insights.

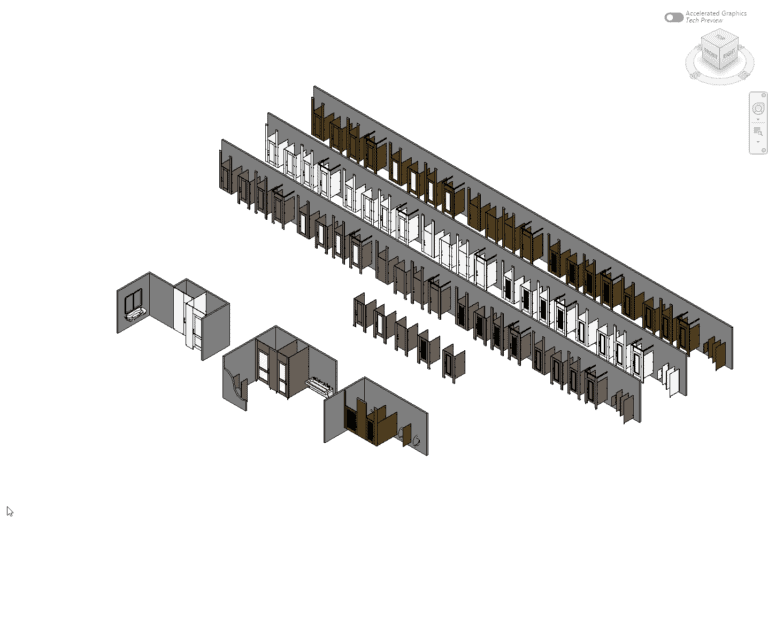

HPL toilet partition components are typically constructed by applying thin layers of high-pressure laminate (usually around 0.039″ thick) to both faces of a core material, most commonly particle board. The total thickness of a component is determined by the core material thickness plus the thickness of the laminate layers and adhesive on both sides.

- Standard door thickness: 1-1/4″

- Standard panel thickness: 7/8″

- Standard pilaster thickness: 1-1/4″

These thicknesses provide a sturdy construction while maintaining a sleek, modern appearance. The use of HPL over a core material offers excellent durability and impact resistance, making it ideal for high-traffic commercial restroom environments.

Standard compact laminate is Class B fire rated. Class A fire rating is an additive option. Note that Class A is considerably more expensive.

High Pressure Laminate partitions are often a good choice when surfaces must be free of germs. Some, but not all, high pressure laminate products can be manufactured with an antimicrobial coating. We recommend cleaning be done simply with soap and water, but most commercial cleaning products do not diminish material performance.

High Pressure Laminate components can be manufactured with a wide range of patterns, colors, and even printed images. Contact us to explore available design options.

Here is more information about high pressure laminate toilet partitions, for those wanting to go a little deeper.

AKA (Also Known As)

High Pressure Laminate (HPL) partitions are known by various names in the industry. Designers and specifiers may encounter terms such as plastic laminate partitions, PLAM partitions, decorative laminate partitions, or laminate toilet partitions. These alternative designations all refer to the same durable and versatile material.

Edge Treatments

Edge treatment of HPL partitions is important for both aesthetics and durability. Edge banding protects the core material and creates a finished look. Designers can choose matching edge banding for a seamless appearance or contrasting banding for added visual interest. This flexibility supports a wide range of design approaches.

Environmental Considerations

HPL partitions can be an environmentally conscious choice. Many HPL and core materials are recyclable at the end of their lifecycle. Low-emission options are available, certified for minimal volatile organic compound (VOC) emissions. HPL partitions can also contribute to LEED credits in several categories, supporting sustainable design goals.

Longevity and Wear Resistance

HPL partitions are known for exceptional durability. Their surfaces are highly resistant to scratches, impacts, and general wear and tear. The color stability of HPL ensures that chosen colors and patterns remain vibrant under normal use conditions, preserving the design integrity over time.

Climate Considerations

HPL partitions perform well across various climatic conditions. They are moisture-resistant, suitable for standard restroom environments. HPL maintains its structural integrity across typical indoor temperature ranges and offers good UV resistance. It also demonstrates excellent dimensional stability, with minimal expansion or contraction due to environmental changes.

Frequently Asked Questions

Can custom colors or patterns be ordered?

Yes, custom options may be available. Consult with Ironwood Manufacturing for specific requirements.

What is the typical lifespan of High Pressure Laminate?

With proper maintenance, High Pressure Laminate can last 10-15 years or more, depending on usage conditions.

Are High Pressure Laminate environmentally friendly?

The engineered wood core can contribute to sustainable design goals. Check with Ironwood for specific environmental certifications.

Can HPL be used in shower areas?

HPL is not recommended for areas with prolonged exposure to water or steam. Consider compact laminate for these applications.

Are antimicrobial options available in HPL?

Yes, some manufacturers offer antimicrobial HPL options. Contact Ironwood Manufacturing for specific availability.

How does HPL compare to compact laminate in durability?

HPL is less durable than compact laminate. For high-traffic or abusive environments, compact laminate is recommended.

If you can’t find the answer you’re looking for, feel free to reach out to us directly and we’ll be happy to assist you!

Featured High Pressure Laminate Bathroom Stalls

GalleryBrowse through examples of high-pressure laminate bathroom stalls, highlighting their aesthetic appeal and practical benefits.

Explore Portfolio