Solid Surface Partitions

Design With Solid SurfaceSolid surface offers a unique look, a wide variety of patterns and finishes, good damage resistance, and excellent repairability.

Lead Time: 14 Weeks

Budget: $$$$

Solid Surface Vendors

What Solid Surface Options are Available for Restroom Partitions?

We provide materials from multiple manufacturers and have an extensive selection of patterns and colors to select from. You may verify the availability of your color and pattern using the links below. For additional options please contact us, we are happy to assist.

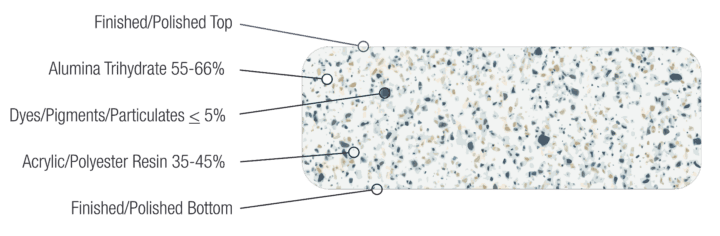

What is Solid Surface?

Solid surface is a non-porous, homogeneous material made from acrylic polymer resins, pigments, and fire-retardant fillers. It offers a seamless appearance, durability, and repairability, making it ideal for high-traffic commercial restrooms.

Solid Surface Use Cases

Application

Solid surface is recommended for high-traffic areas requiring durability and ease of maintenance.

Airports

Shopping Malls

Educational Facilities

Healthcare Facilities

Corporate Restrooms

Casinos

Churches

Country Clubs

AND MORE

Considerations When Using Solid Surface

Solid surface offers numerous advantages, but certain features should be evaluated to ensure it meets your project’s requirements.

FeaturesAesthetic

Solid surface creates a sleek, modern look with no visible seams (except for non-solid patterns), enhancing the overall aesthetics of the restroom.

Repairability

Minor scratches, damages, and graffiti artists’ strikes can be easily buffed out, maintaining the partition’s appearance over time.

Moisture Resistance

The non-porous nature of solid surface makes it highly resistant to moisture, preventing issues like swelling or warping.

Color and Pattern Options

A wide range of colors and patterns are available, allowing for design flexibility and coordination with other restroom elements.

Installation Complexity

The weight and need for seamless joints may increase installation time and complexity compared to lighter materials.

Durability

Solid surface is known for its durability, making it suitable for high-traffic areas where wear and tear are concerns.

Cost

Solid surface is more expensive than some other partition materials, which may impact budget considerations for larger projects.

Weight

Solid surface partitions are heavier than some alternatives, requiring appropriate structural support and hardware.

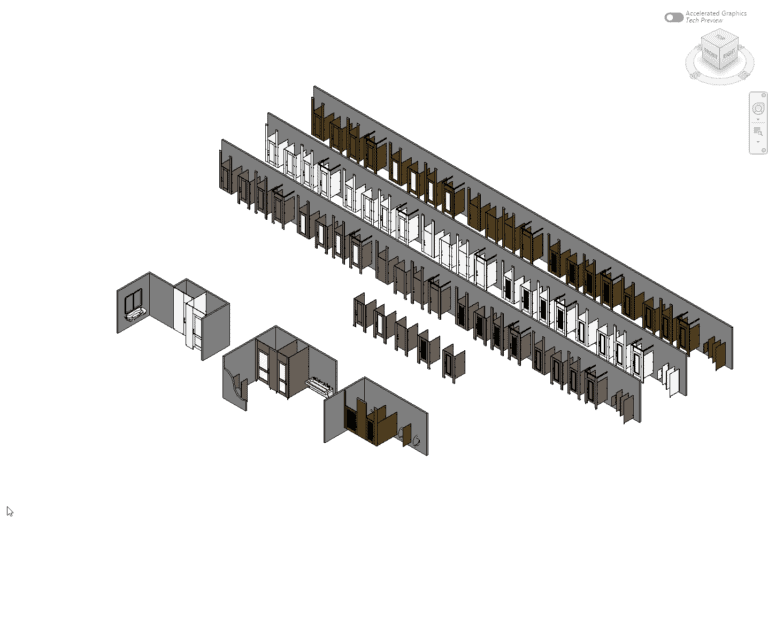

How to Specify Ironwood

Follow our easy three-step process to start using Solid Surface in your design:

The Process- 1

Go to the Configurator

The Ironwwood Configurator will help guide your choices of material, mounting style, door option, hardware, etc. to specify your toilet partitions.

- 2

Generate Your Specification

Once you have made your selections, the configurator will generate a spec and other helpful resources for you.

- 3

Contact Us With Any Questions

Call us at 360-965-6590 or email us at specs@ironwood-mfg.com.

Deeper Dive & Resources

Most manufacturers of solid surface materials have maximum sheet widths of 30″ and maximum thicknesses of 1/2″. Ironwood Manufacturing creates toilet partition components by bonding two of these 1/2″ thick sheets to form 1″ thick panels. This process creates rigid, durable components with finished surfaces on both sides. The edges are routed and finished to create a seamless appearance.

For partition components wider than 30″, a butt-joining process is used. This involves carefully aligning and bonding multiple pieces together, followed by sanding to create an imperceptible seam in solid colors. Non-solid color patterns will have a slightly perceptible seam, depending on the pattern. This butt-joining process allows for the creation of larger panels while maintaining the material’s seamless aesthetic.

Solid surface is available in various finishes. The standard finish offered by Ironwood Manufacturing is matte, which helps to conceal minor scratches and reduces the visibility of wear over time.

Maintenance of solid surface partitions is relatively straightforward:

- Regular cleaning with mild soap and water is sufficient for day-to-day maintenance.

- Avoid using abrasive cleaners or harsh chemicals, as these can damage the surface.

- Minor scratches can often be buffed out using fine-grit sandpaper, followed by refinishing to match the surrounding area.

- Professional repair may be necessary for deeper scratches or damage.

Solid surface doors are quite heavy. To minimize injury risks and product damage, Ironwood solid

surface doors always include a closer to limit the closing speed. Mounting this closer over the door

requires the presence of either headrail or a transom. It also typically requires the door to be at least

71” high so it reaches the closer, which must be mounted high enough to avoid head injuries.

Frequently Asked Questions

Are there any environmental considerations when specifying solid surface partitions?

Many solid surface products contain recycled content and can contribute to LEED credits. Some manufacturers also offer take-back programs for end-of-life recycling. It is advisable to check with specific manufacturers for their environmental certifications and initiatives.

Can solid surface be combined with other materials in partition design?

Yes, solid surface can be effectively combined with other materials such as wood veneer, high pressure laminate, or compact laminate for unique design aesthetics. Ironwood Manufacturing can provide guidance on integrating multiple materials in partition designs.

How does the color consistency of solid surface compare to natural materials?

Solid surface offers excellent color consistency compared to natural materials. While there may be slight variations between production batches, these are typically minimal and can be managed through proper planning and ordering.

Should any patterns or finishes be avoided in solid surface?

Yes, there are patterns and finishes which do not perform well in restrooms. Designs should avoid dark patterns, as these tend to haze and fog in restroom usage. High gloss finishes also do poorly in the restroom setting.

What options are available for repairing damaged solid surface partitions?

Minor scratches can often be buffed out on-site. For more significant damage, the affected area can be cut out and seamlessly replaced by a skilled professional.

How does solid surface perform in terms of fire resistance?

Solid surface materials typically have good fire resistance properties. They are often classified as Class A or B for flame spread and smoke development. However, specific ratings can vary by manufacturer, so it is important to check the specifications for the chosen product.

Can solid surface partitions be used in shower applications?

Yes, solid surface is an excellent choice for shower partitions due to its non-porous nature and moisture resistance. It performs well in wet environments and is easy to clean and maintain.

If you can’t find the answer you’re looking for, feel free to reach out to us directly and we’ll be happy to assist you!

Featured Solid Surface Stalls

GalleryBrowse through examples of solid surface bathroom stalls, highlighting their aesthetic appeal and practical benefits.

Explore Portfolio