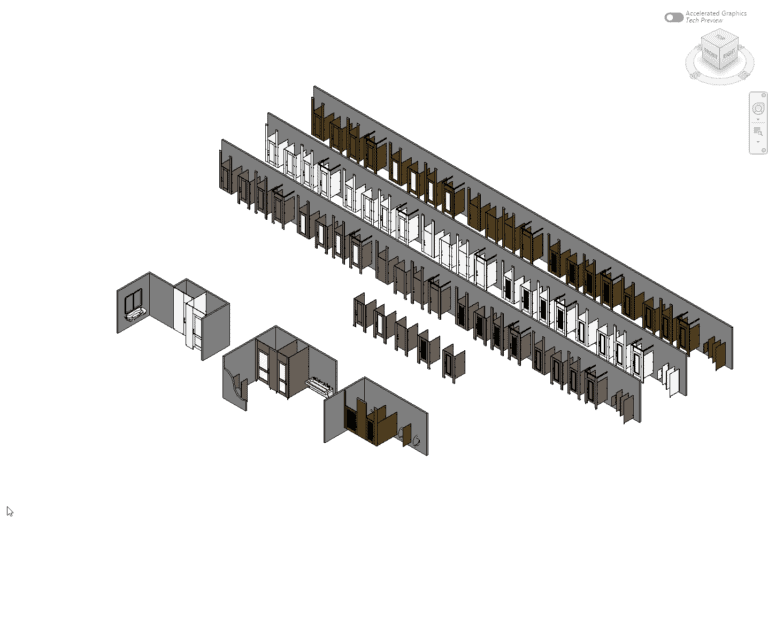

Wood Veneer Partitions

Design with Wood VeneerWood veneer brings warmth, sophistication, and a touch of nature to commercial restroom designs. Create stunning, high-end spaces that leave a lasting impression on visitors.

Lead Time: 8 Weeks

Budget: $$$$

Wood Veneer Vendors

What Veneer Species and Cuts are Available for Partitions?

We offer a full range of commercially available species and cuts to specify from. While our standard veneers are Flat Cut Walnut, Flat Cut White Oak, and Rift Cut White Oak, many other domestic and exotic selections exist. You may verify the availability of your cut and species using the links provided. For additional options, contact us, we are happy to assist.

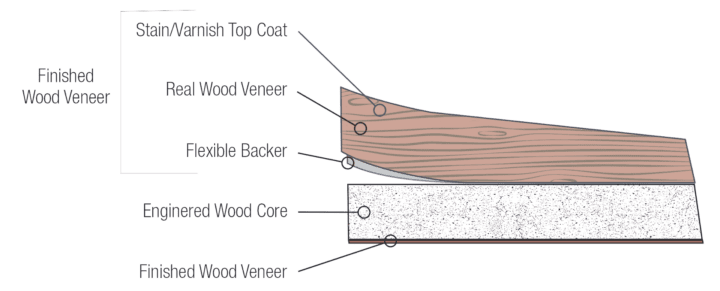

What is Wood Veneer?

Wood veneer is a thin layer of real wood, typically 0.039″ thick, adhered to both sides of an engineered wood core. This process allows for the beauty and variety of natural wood on the surface while the core material maintains the stability and consistency needed for toilet partition components. Unlike high pressure laminates, no two sheets of natural veneer look the same.

Wood Veneer Use Cases

Application

Wood veneer is an ideal choice for upscale commercial restroom environments where elegance, warmth, and a touch of luxury are desired. Its natural beauty and range of available finishes allow designers to create sophisticated spaces that elevate the overall aesthetic of high-end facilities.

High-End Offices

Executive Areas

Wedding Venues

Hotels & Resorts

Upscale Restaurants

Fine Art Museums

Wineries

Country Clubs

AND MORE

Considerations When Using Wood Veneer

Wood veneer offers numerous advantages, but certain features should be evaluated to ensure it meets your project’s requirements.

FeaturesAesthetic

Wood veneer toilet partitions offer a premium feel. Its unique grain, texture, and tone give wood veneer natural beauty. Depending on the species, Ironwood veneer partitions have the veneer leaves either book or slip-matched across the face.

Design Choices

Domestic species such as cherry, maple, and walnut are available. Exotic species, such as mahogany and wenge are also available. Wood veneer also offers the flexibility of being stained to match other elements of a restroom.

Moisture Resistance

Wood veneer partitions are designed for low-humidity, indoor environments. They are not suitable in areas with high moisture levels or direct water exposure, as this can lead to delamination or warping.

Premium Price

Raw wood veneer is less expensive than some materials, like engineered stone, but it is costly and requires the additional steps of sanding, staining, and finishing. This makes wood veneer partitions 2-4 times more expensive than comparable laminate or metal partitions.

Color and Pattern Variability

Natural wood veneer has variations in grain and color. We strive to source materials which are uniform across sheets to minimize this variation. However, since individual components are manufactured from different veneer sheets, grain and color variation between components (doors, panels, pilasters, screens) is to be expected.

Durability

Wood veneer partitions are less durable than some alternative materials. They are not recommended for high-traffic or potentially abusive or humid environments where they may be prone to damage.

Light Sensitivity

Natural veneers are photosensitive and will likely change color over time if exposed to ultraviolet light. This natural aging can add character but should be considered in the design process.

Sustainable

When sourced responsibly, wood veneer can be an environmentally friendly choice, using less wood than solid timber while providing a similar aesthetic.

Maintenance

Wood veneers benefit from periodic care to maintain their appearance. Regular cleaning can help preserve their beauty over time.

How to Specify Ironwood

Follow our easy three-step process to start using Wood Veneer in your design:

The Process- 1

Go to the Configurator

The Ironwwood Configurator will help guide your choices of material, mounting style, door option, hardware, etc. to specify your toilet partitions.

- 2

Generate Your Specification

Once you have made your selections, the configurator will generate a spec and other helpful resources for you.

- 3

Contact Us With Any Questions

Call us at 360-965-6590 or email us at specs@ironwood-mfg.com.

Deeper Dive & Resources

Gain a deeper understanding of Wood Veneer by exploring resources and expert insights.

Wood veneer is available in a variety of species, each offering unique characteristics:

- Oak (Red and White)

- Walnut

- Maple

- Cherry

- Mahogany

- Exotic species (upon request)

The cut of the wood also affects its appearance:

- Flat Cut (Plain Sliced): Casual, flowing grain pattern

- Quarter Cut: Straight, uniform grain pattern

- Rift Cut: Straight grain with minimal fleck

Wood veneer offers several hygiene-related advantages:

- Smooth surface: The finished surface of wood veneer is smooth and non-porous, making it relatively easy to clean and maintain.

- Antimicrobial options: Some finishes can be applied to wood veneer that have antimicrobial properties, helping to inhibit the growth of bacteria and other microorganisms.

- Zero Sightline: Ironwood Manufacturing offers options that eliminate sight lines between components, enhancing privacy and hygiene.

It is important to note that wood veneer is more susceptible to moisture damage than some other materials. Regular cleaning with limited amounts of mild soap and water (wiped dry) and proper maintenance are crucial to ensure long-term hygiene and performance.

Wood veneer offers extensive options:

- Species selection: Choose from a wide range of wood species, each with unique grain patterns and natural coloration.

- Cut options: Select from various veneer cuts (e.g., plain sliced, quarter sliced, rift cut) to achieve different visual effects.

- Matching techniques: Specify how veneer sheets are matched (e.g., book match, slip match) for desired aesthetics.

- Staining and finishing: Custom stain colors and finish types can be applied to achieve specific design goals.

- Inlays and patterns: Create unique designs by incorporating inlays or patterns using different wood species or cuts.

- Non-standard sizes: Partition components can be manufactured to specific dimensions to meet unique space requirements.

- Hardware selection: Choose from various hardware options to complement the overall design aesthetic.

AKA (Also Known As)

Wood veneer partitions may also be referred to as:

- Natural wood partitions

- Architectural wood partitions

- Premium wood partitions

Environmental Considerations

Wood veneer can be an environmentally friendly choice:

- Efficient use of wood: Veneer maximizes the yield from a log compared to solid wood.

- Sustainable sourcing: Look for veneers certified by organizations like FSC (Forest Stewardship Council).

- Low-VOC options: Many finishes used on wood veneer are now low in volatile organic compounds (VOCs).

- Maximum sustainability: For the highest sustainability reconstituted or recon wood veneer products can be specified.

Climate Considerations

Wood veneer performance can be affected by climate:

- Avoid extreme humidity fluctuations: Stable humidity levels help prevent warping or delamination.

- Temperature consistency: Maintain consistent temperatures to prevent expansion and contraction cycles.

- Acclimatization: Allow wood veneer components to acclimatize to the installation environment before assembly.

Frequently Asked Questions

How does the durability of wood veneer compare to other partition materials?

Wood veneer is less durable than materials like compact laminate or solid surface. It performs well in moderate-use environments but is not recommended for high-abuse areas.

What core material is used for wood veneer partitions?

Wood veneer is typically applied to a core of 45-pound industrial-grade particle board. For certain applications, such as stile and rail doors, an engineered wood core may be used for added strength.

How thick are wood veneer partition components?

The wood veneer itself is typically 0.039″ thick. When applied to both sides of the core material with adhesive, it adds about 0.090″ to the overall thickness of the component.

Are there sustainable or eco-friendly options for wood veneer partitions?

Many wood veneer options can be sourced from sustainably managed forests.

If you can’t find the answer you’re looking for, feel free to reach out to us directly and we’ll be happy to assist you!

Featured Wood Veneer Bathroom Stalls

GalleryBrowse through examples of wood veneer bathroom stalls, highlighting their aesthetic appeal and practical benefits.

Explore Portfolio